|

||||||||

| TRIPLE OFFSET BUTTERFLY VALVES | |||

|

|||

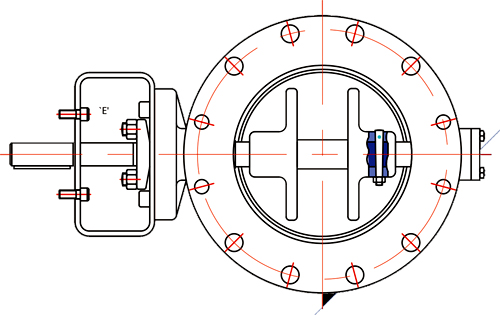

Compared to a concentric valve, there are three

eccentricities in this product which offers various

benefits compared to a traditional valve. The first

eccentricity (seal ring offset from the shaft centre

line) ensures that the seal and seat ring is in one

piece without shaft interruption. The second

eccentricity (shaft offset from pipe centre line)

gives the non-symmetric trim design. This is

useful for higher safety integrity applications

where fail to open/close features can be used to

assist required fail safe position with correct

installation of valve to flow / high pressure

direction. It also ensures that the seal does not

contact the seat ring at full open position. The

third eccentricity (seat and seal cone centre lines

being inclined to pipe centre line) completely

eliminates rubbing between seat and seal

throughout 90° rotation. Our design ensures that the seal contacts the seat ring only at the final stage of closing and there is no rubbing / skidding thereby precluding any galling and wear. The resiliency of the disc seal ensures that it adjusts to the seat ring surface thereby developing uniform compressive force between the seating surfaces. This guarantees perfect bubble-tight sealing contact. not only during normal operating conditions but also during thermal cycling. |

|||

SOME OF THE KEY FEATURES/BENEFITS OF OUR DESIGN ARE OUTLINED AS FOLLOWS : |

|||

Copyright @ R&D Multiples All Rights Reserved.